- Manufacturing

- 01.04.2025

Smart Factories for Smart Snacks: How SIX ERP Transforms Food Production

Transforming a Potato Chips Factory into a Smart, Scalable Production Facility with SIX ERP

Dr. Andreas Maier

01.04.2025

“ Smart manufacturing isn’t just about machines doing the work; it’s about creating systems that think, adapt, and evolve with every challenge. “

As the CEO and mastermind behind our ERP implementations, I’ve seen firsthand how manufacturing is evolving. It’s no longer just about efficiency - it’s about intelligence, adaptability, and staying ahead of the curve. At SIX ERP, we don’t just implement software; we engineer smart, scalable solutions that transform production lines into data-driven, automated ecosystems.

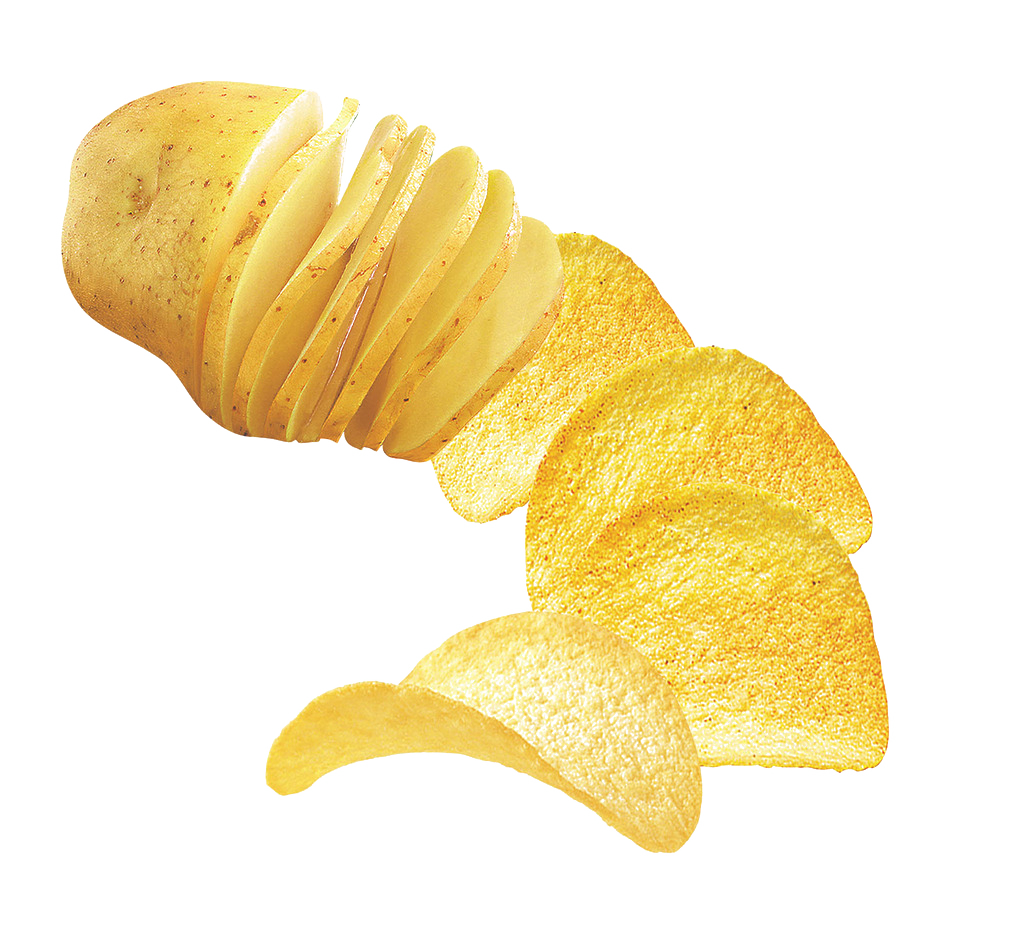

One of our most exciting challenges? Equipping a new potato chips factory with a fully automated, sensor-driven production process. From the initial digital simulation to real-world integration, our goal is to ensure seamless operations, minimal waste, and maximum efficiency. This is the story of how we approach complex manufacturing problems - and why a smart factory is the future of food production.

The Smart Approach to Food Production

When a client approached us with the challenge of equipping their new potato chips factory with cutting-edge automation, we knew this wasn’t just another manufacturing setup. Unlike traditional industrial production, food processing demands precision, consistency, and real-time adaptability. Every batch must meet strict quality standards while minimizing waste and optimizing efficiency. That’s where SIX ERP comes in. Our approach? Simulate the entire production process digitally before a single potato hits the fryer - ensuring a seamless, data-driven transition from concept to factory floor.

Understanding the individual Complexities of Food Production

Unlike standard industrial manufacturing, where raw materials often have predictable properties and long shelf lives, food production operates under entirely different constraints. In a potato chips factory, we deal with perishable ingredients, variable raw material quality, and strict food safety regulations. Every step of the process - from slicing and frying to seasoning and packaging - must be precisely controlled to ensure product consistency. Even minor fluctuations in oil temperature or seasoning distribution can lead to waste and inefficiencies.

This is where a smart ERP system makes all the difference. By integrating real-time monitoring, automated adjustments, and predictive analytics, we ensure that production remains efficient, adaptable, and fully compliant with industry standards. The challenge isn’t just making chips - it’s making them smartly, with minimal waste and maximum quality.

SIX ERP – Where Every Click Moves Your Business Forward.

Simulation Before Implementation

Before setting foot on the factory floor, we take a smart-first approach - digitally simulating the entire production process to eliminate inefficiencies before they arise. Using Bill of Materials (BOM), Routings, and Operations, we create a virtual model of the factory, mapping out every step from raw potato intake to packaged chips ready for shipment.

This simulation isn’t just a theoretical exercise - it’s a stress test for reality. We identify potential bottlenecks, optimize workflows, and refine production parameters without disrupting real-world operations. By analyzing processing times, machine workloads, and ingredient usage, we ensure that the system is optimized before a single sensor is installed. The result? A data-driven, intelligent production setup that operates smoothly from day one.

Challenges & Solutions During Implementation

No matter how precise our simulations are, the factory floor always presents unexpected challenges. As we integrate SIX ERP with real-world production, we often encounter sensor calibration issues, machine response delays, or unforeseen process inefficiencies. For example, during one implementation, we discovered that the oil temperature sensors had a slight lag, leading to inconsistencies in frying times - something the simulation couldn’t fully predict.

Rather than treating these as setbacks, we see them as opportunities for smart optimization. Our team works closely with factory operators, fine-tuning sensor feedback loops, adjusting automation thresholds, and ensuring that real-time adjustments happen seamlessly. By combining technical expertise with hands-on problem-solving, we make sure that SIX ERP doesn’t just control production - it continuously improves it. This collaborative, adaptive approach ensures that the factory doesn’t just work - it works smarter with every iteration.

Results & Client Benefits

With the ERP fully integrated and fine-tuned to real-world conditions, the impact becomes clear. Production efficiency improves, waste is minimized, and quality control reaches new levels of precision. By automating critical processes and leveraging real-time analytics, the factory can now adjust to fluctuations in raw material quality, optimize energy consumption, and ensure consistent product output - without constant manual intervention.

For the client, this means more than just a smoother operation. They gain a factory that is smarter, more responsive, and built for growth. With a scalable ERP backbone in place, they can expand production, introduce new product lines, and adapt to market changes with minimal disruption. What started as a complex challenge becomes a future-proof, data-driven manufacturing system - designed to keep chips crispy and operations even crisper.

Conclusion & Takeaways

As we continue the integration of SIX ERP in the potato chips factory, we're seeing firsthand the value of our smart approach. While traditional manufacturing systems often focus on fixed processes, food production requires adaptability, real-time control, and precision - elements that SIX ERP delivers in abundance.

Our ongoing work combines digital simulations, real-time monitoring, and collaborative troubleshooting to ensure a smooth transition from concept to operational reality. As the integration progresses, we’re refining processes, optimizing automation, and continuously adapting the system to meet the client’s evolving needs.

This is more than just an implementation; it's a step-by-step transformation toward a smart factory. As we fine-tune and expand the system, the results are already evident - greater flexibility, improved production efficiency, and a future-proof foundation for growth. For us, it’s a reminder that every challenge is an opportunity to make things smarter, more efficient, and scalable.

Looking Ahead: We’re Here to Help You Solve Your Unique Manufacturing Challenges

If you're facing a complex manufacturing challenge, we’re here to help. Whether it’s streamlining operations, automating processes, or integrating smart technology into your production line, our team has the expertise and experience to turn your vision into reality. We understand that every factory is unique, and that's why we approach each project with a tailored solution. Have a problem? Ask us, and we’ll do our best to provide a smart, scalable solution that fits your needs. Let’s transform your production process together.

About the author

Andreas Maier is a results-driven CEO with nearly 30 years of experience in ERP, digital transformation, and IT consulting. He has held leadership positions in Fortune 100 companies such as rentalcars.com (PCLN) and Intrasoft International, a leading EU-based R&D software vendor. With a Ph.D. in Neural Networks from the University of Cologne, Andreas combines deep technical expertise with a strategic approach to business process optimization.

As the founder and co-founder of multiple successful startups, including XXL Cloud Inc., eShopLeasing Ltd, and WDS Consulting SA, his expertise lies in ERP consulting, IT strategy, and process automation. His work is focused on helping businesses implement scalable ERP solutions, streamline operations, and drive digital transformation.

Related articles

Beyond the Dashboard:

The term “data-driven” has become a cornerstone of modern business discourse. Yet, for many organizations, the promise of data-fueled success remains elusive. Despite billions invested in sophisticated analytics platforms, a...

CRM Systems for SMEs

As a business owner, you know the importance of managing customer relationships. An effective Customer Relationship Management (CRM) system is essential for any small to medium-sized enterprise (SME). CRMs enable...