- Artificial Intelligence

- 01.11.2025

Agentic AI + MCP: The New Nerve Center of ERP

How autonomous systems, real-world data, and modern control protocols turn ERP from record-keeping into resource prediction.

Dr. Andreas Maier

01.11.2025

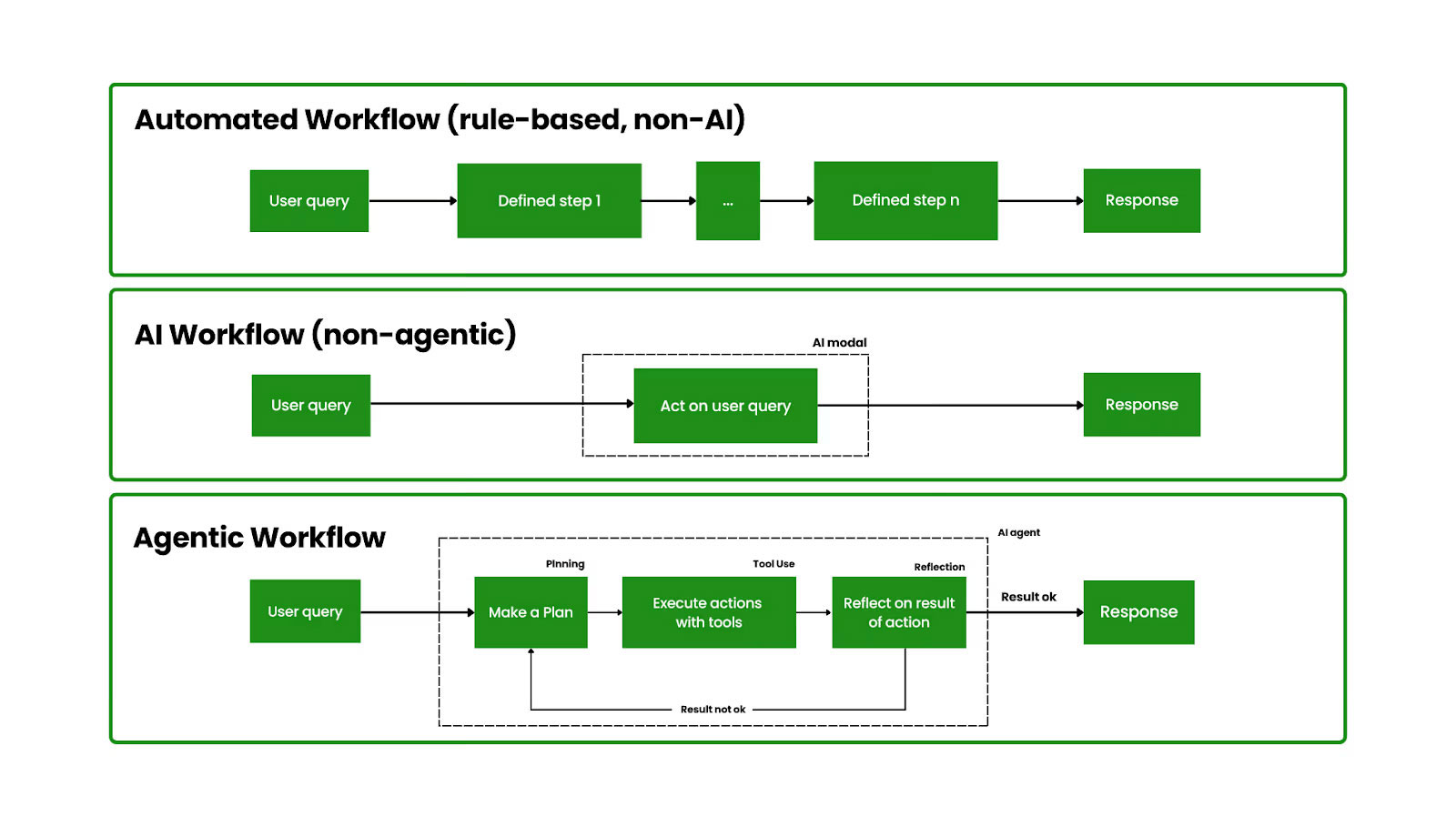

Agentic AI is the next step after large language models learned to read and write. Instead of waiting for a user to ask something, an agent can set a goal, break it into steps, choose which tools to use, check if the result makes sense, and try again if it doesn’t. In an ERP setting, that means no longer scrolling through reports to figure out what went wrong. The system can spot a pattern in sales, check raw-material stocks, look at machine calendars, and draft a plan that changes purchase orders and work orders with clear reasons for each step. It can explain its recommendation in plain language, show the data behind it, and prepare the approval so a manager can say yes or no in seconds. This shift turns ERP from a passive record of what already happened into an active partner that works through problems, tests options, and gets closer to the best decision with each loop.

1) From LLMs to Agentic Systems

Why “knowing” isn’t enough—systems must decide and act.

Large language models are good at understanding questions and producing answers, but a business needs more than answers—it needs action. Agentic systems add planning, tool use, and feedback so they can move from “what is the lead time?” to “lead time increased; here are three safe changes to protect delivery dates, with cost and risk for each.” They use the ERP’s own APIs, run small simulations, and compare outcomes before suggesting a path. When the result is weak, they ask for more data or try a different tool. When the result looks strong, they present a clear summary, the steps they took, and the exact changes they want to apply. This closes the gap between analysis and execution and helps teams make faster, more reliable choices.

2) What MCP Servers Actually Do for ERP

Machines speak protocols; MCP lets AI speak operations.

An MCP (Model Context Protocol) server is a secure doorway that shows agents only the tools and data they should see, nothing more. In practical terms, it exposes safe functions like “create purchase order,” “read stock by lot,” “schedule maintenance,” or “get QA spec,” each with permission checks and input rules. Instead of building one-off integrations for every use case, you define these tools once, document them, and let agents call them under policy. The ERP stays in control, because every call is logged, rate-limited, and tied to a role. If a task needs a human step—like approving a price change—the MCP server can return an approval card rather than making the change directly. This pattern lets companies add new agent skills quickly while keeping their systems stable and compliant.

Seamless, Smart, and Stress-Free – Welcome to SIX ERP.

3) The Data Shift: From Warehouses to Live Context

Real-life data is the fuel; context is the combustion chamber.

Warehoused data is useful for learning from the past, but operations depend on what is happening right now. Agentic ERP becomes powerful when it reads live signals: sensor data from machines, ETA updates from suppliers, pick-rate trends in the warehouse, and even outside factors like energy prices or weather delays. With current context, agents can tell if a plan will still work before it fails. They can pause a risky batch, reorder the production sequence to avoid a changeover, or split a shipment to hit a service-level target. Combining live data with a knowledge layer—procedures, contracts, and quality rules—keeps actions safe and consistent. The result is less firefighting and more quiet, steady flow.

4) Intelligent Business Analytics: From Descriptive to Predictive (and Prescriptive)

Dashboards inform; agents transform.

Classic dashboards tell you what happened yesterday; intelligent analytics look forward and suggest what to do next. Agents run forecasts that balance demand swings with supplier reliability and cash limits, not just averages. They detect weak signals—like a small rise in rejects on one line—and check upstream causes before a big scrap event appears. They propose actions, such as adjusting batch size, changing a supplier for one component, or moving a delivery window to match capacity, and they include the expected impact on margin, service level, and inventory. Because the agent keeps running, it updates the plan as new facts arrive, so the business stays in a predictive, not reactive, mode.

5) Resource Prediction > Resource Planning

Plan once is yesterday; plan continuously is tomorrow.

Traditional MRP runs on a schedule and gives one answer. Agentic ERP runs continuously and updates plans as conditions move. It estimates when a machine will be free based on real runtime, not only the calendar. It predicts labor gaps from shift swaps and suggests temp coverage only where it matters most. It checks transport capacity before promising ship dates, and it builds small buffers where the risk is highest, not everywhere. When a supplier slips, the agent compares alternates, calculates new costs and lead times, and shows a ranked list of fixes. Planning becomes a living process that learns from results and keeps the whole system close to its targets with fewer surprises.

6) Industry 4.0: Closing the Loop Between Bits and Atoms

IoT, OPC UA, and digital twins meet agent orchestration.

Industry 4.0 connects machines, sensors, and systems; agentic ERP gives that connection purpose. With machine data flowing in, an agent can spot wear patterns, schedule maintenance before breakdown, and order parts in time to avoid rush fees. With quality rules in its context, it can compare measurements to tolerance and flag drift early, reducing rework. With a digital twin of the line, it can test a new sequence virtually, estimate cycle time changes, and only then update the real schedule. Because each step is explained and logged, engineers and managers stay in control while the system handles the routine adjustments that keep output stable and costs lower.

7) Human Control, Clear Guardrails

Autonomy with accountability.

Agents act inside boundaries that you define: who can read what, who can write where, and what needs approval. Every action is recorded with inputs, outputs, and the reason the agent believed it was safe. Sensitive operations—like pricing, payroll, or regulated data—stay behind stricter checks, and the agent routes a clear approval message when needed. Because the system explains itself, teams can trust it faster, and audits move quicker. This is not “hands off”; it is “hands on the right controls,” where people spend time on choices that matter rather than retyping data or chasing status.

8) Architecture Blueprint: How It Fits Together

Pragmatic stack for production, not prototypes.

A solid agentic ERP stack has a few simple layers. The MCP layer defines safe tools and data views. A context layer stores procedures, specs, and documents for quick lookup so the agent follows company rules. Event streams carry updates from machines, MES, WMS, CRM, and outside feeds into one place. The agent runtime plans steps, calls tools, checks results, and tries again if needed while meeting cost and latency limits. A policy layer enforces roles, quotas, and audit trails. The user layer brings this into the screens people already use: chat assistants next to work orders, proactive alerts, and one-click approvals that apply changes directly in ERP. Each layer is small on its own, but together they make a system that learns and adapts without breaking the core.

9) High-Impact Use Cases You Can Deploy First

Start where value is obvious and measurable.

Begin with slices that show fast wins. Demand and supply forecasting that respects risk improves service without bloating stock. Predictive maintenance lowers downtime and spare-part panic buys. Dynamic scheduling that considers energy tariffs and changeover time cuts cost per unit. QA copilots reduce defects by catching drift earlier and guiding operators with clear steps. Finance simulators link plans to cash, so leaders can see the effect of a delay or discount before they commit. Each use case shares the same backbone—MCP tools, context, and events—so every win makes the next one faster.

10) Measurable Outcomes

From “AI vibes” to business results.

Agentic ERP should prove itself with numbers the business already tracks. Look for higher forecast accuracy, better on-time-in-full, shorter lead times, fewer unplanned stops, less scrap, and a healthier cash-conversion cycle. Check that recommendations include reasons, expected impact, and a way to measure if the change worked. Over time, the agent should learn which tactics perform best in your environment and lean on them more. The point is not fancy language; the point is steady, visible improvements that keep piling up.

Are you facing challenges in your business that you're trying to solve?

Let’s connect for a FREE 30-minute consultation call and see how I can help you move forward.

11) Security, Compliance, and Trust by Design

Safe by default, not as an afterthought.

Trust starts with design. Tools exposed through MCP are least-privilege and read/write separated. Sensitive data can be masked or kept in its region. Validation happens both before and after actions, so a bad input does not turn into a bad transaction. Red-team prompts and test cases help catch failure modes early. Every step is logged with who, what, when, and why, so compliance checks move quickly. If something goes wrong, rollback paths are clear. This keeps operations safe while still allowing useful automation to grow.

12) The SIX ERP POV: Smart Applications, Not Just Smart Answers

Beyond resource planning—into resource prediction.

At SIX ERP, we build agent skills into the workflows teams use every day. Our MCP servers expose governed actions across Manufacturing, Inventory, Finance, and CRM, so agents can read live context and take safe steps that move the business forward. We focus on small, clear wins first—like stabilizing lead times or reducing scrap—and then scale the same pattern across departments. The goal is simple: make the ERP smart enough to predict resource needs, propose solid plans, and help people apply them with confidence.

13) Migration Path: How to Get There in Weeks, Not Years

Thin slices, fast wins, steady expansion.

Pick one process where delay or waste hurts the most. Connect the needed data streams, publish a few safe tools through MCP, and run the agent in shadow mode to compare its plan to the current one. When results look good, switch to human-in-the-loop approvals so changes flow through with one click. After a stable period, allow the agent to automate low-risk actions while keeping people on exceptions. Reuse the same tools and patterns for the next process. This steady path avoids big-bang risk and builds trust at each step.

14) The Near Future

Autonomous cells, multi-agent swarms, and market-aware factories.

Production cells will schedule themselves against live demand, supplier risk, and energy cost. Multiple agents will coordinate across plants to trade capacity, balance rush orders, and keep service promises. Procurement will see risk early and act before shortages bite. Sustainability targets will sit next to cost and throughput in every plan, not as an afterthought. As these parts connect, the ERP will do more than report the state of the business—it will guide it toward better outcomes, hour by hour.

15) Call to Action

Make your ERP agentic—start this quarter.

If you want fewer surprises and steadier results, begin with one focused slice and let the numbers speak. SIX ERP is ready with agentic workflows, MCP-based integrations, and the guardrails needed for real operations. We help you move from reports to recommendations, from one-time plans to continuous prediction, and from busy work to better work. Let’s build the smart factory together—practical, measurable, and ready for what’s next.

About the author

Andreas Maier is a results-driven CEO with nearly 30 years of experience in ERP, digital transformation, and IT consulting. He has held leadership positions in Fortune 100 companies such as rentalcars.com (PCLN) and Intrasoft International, a leading EU-based R&D software vendor. With a Ph.D. in Neural Networks from the University of Cologne, Andreas combines deep technical expertise with a strategic approach to business process optimization.

As the founder and co-founder of multiple successful startups, including XXL Cloud Inc., eShopLeasing Ltd, and WDS Consulting SA, his expertise lies in ERP consulting, IT strategy, and process automation. His work is focused on helping businesses implement scalable ERP solutions, streamline operations, and drive digital transformation.

Related articles

Top 10 ERP Features Warehouses and Distributors Need

If you are in the business of warehousing and distributing goods, then you know that having a good ERP system is critical to your success. But with so many different...

Human Resource Management in ERPs

Human Resource Management (HRM) is a process of managing people in organizations. In the traditional sense, HRM functions included recruitment, selection, training, and compensation. However, in the modern era, the...