- ERP Systems

- 19.12.2022

ERP Integrations - To Do or Not To Do?

ERP integrations can be a great way to customize your system to fit your company's processes better - but they're not always the best solution.

Dr. Andreas Maier

19.12.2022

“ Reduce complexity through standardization. “

This blog post will explore when you should and shouldn't execute an ERP integration.

ERP integrations can offer a lot of potential benefits for companies. They can provide a way to better fit the software to the company's specific processes and needs and improve data flow between systems. However, before considering an integration, it's essential to get educated on existing software functionality and explore ways to change your procedures to match the software. Utilize built-in tools for personalization and bolt-on functionality where possible. There are a bunch of good reasons why you might want to consider integration, including:

- Data needs to flow between two systems: If you have data that needs to be transferred between two systems regularly, an integration can automate that process and ensure that the data is always accurate and up-to-date.

- One system is "alpha": In some cases, one of the systems involved in the integration will be considered the "master" or "primary" system - the "alpha." This usually happens when the company has invested heavily in one system or when one system is more sophisticated. In these cases, it often makes sense to write the interface for the alpha system.

- Writing interface falls on the expert of the alpha system: Another reason you might want to consider an integration is if the person responsible for writing the interface for the alpha system is also an expert on that system. This can help ensure that the interface is well-written and integrated seamlessly with the rest of the system.

Reasons Not to Execute an ERP Integration

However, an ERP integration might not be the best solution in some cases. These include situations where:

- The cost of the integration outweighs the benefits: ERP integrations can be costly in terms of money and time. If the benefits of the integration don't justify the costs, it might not be worth doing.

- It's impossible to integrate with existing systems: There are cases when it might not be possible to combine two systems physically - for example, if they're on different platforms or use other or different technologies. In these cases, trying to force an integration might not make sense or even be counter-productive.

When a company's ERP system does not fit the company's culture or business processes, it often makes sense to integrate the ERP system with one or more third-party applications. This can help the company to customize the ERP system to match its needs better while still taking advantage of the benefits that an ERP system can provide. Integrating an ERP system with a third-party application can be less expensive and time-consuming than completely replacing the ERP system. As a result, it is often a good solution for companies that cannot find an off-the-shelf ERP system that meets their needs.

An ERP integration may be executed for several reasons. In some cases, allowing data to flow between two systems may be necessary to maintain consistency. In other cases, one system must be designated as the "alpha" system, and the expert responsible for writing the interface falls on the person responsible for maintaining that system. Additionally, an ERP integration can help improve efficiency by automating tasks that otherwise need to be performed manually. An ERP integration can save time and money by streamlining the process flow and eliminating redundancies.

Complex and time-consuming

ERP integrations can be complex and time-consuming. They often require the assistance of a consultant or integration specialist. In some cases, hiring a full-time employee to manage the integration may be necessary. Additionally, there is always the risk that something goes wrong during the process, resulting in lost data or downtime. For these reasons, it's essential to consider whether an ERP integration is right for your business. Weigh the potential benefits against the risks and costs before making a decision.

If you're considering integrating another solution into your ERP, it's important to get educated on existing software functionality and explore ways to change your procedures to match the software. Utilizing built-in tools for personalization and modular functionalities where possible can help you get more out of your existing software and avoid the need for costly and time-consuming 3rd party integrations. In many cases, simply changing your procedures to match the software can be a more efficient and effective way to meet your needs. By exploring your options, ensure that you're making an informed decision for your business.

In short, most smaller and medium enterprises cannot afford a custom-made ERP solution. Even if a company has the financial power, in most cases, they lack the expertise to design such a solution.

After all, the good part of the story is that ERP products on the market have matured to offer comprehensive solutions with deep functionality, which can fit many of the everyday situations that were formerly thought only to provide a custom solution.

SIX ERP is the leading provider of highly adaptable ERP solutions. Our products are economical and offer the best choice for companies. We have a wide range of solutions suitable for businesses of all sizes. SIX ERP products are easy to use and offer the most comprehensive range of essential business features, commonly not found in similar products.

The economic scale of specialized providers is the excellent side of acquiring an enterprise resource planning system.

For example, MS Office costs more to develop than the few hundred dollars it effectively licenses for. Another upside is that several thousands of corporate users create a robust framework that quickly reflects on weaknesses in the provided functionality, helping the software provider to become stronger and implement the necessary features for enterprises to operate quickly and effectively.

The downside is that the ERP may not fully synchronize with a company's culture. This is when most business owners start to think about custom ERP integrations.

In short, most companies can't afford a custom ERP solution, nor do they have the expertise to design one. Still, business owners want to provide their organizations with all the benefits of customized systems.

Seamless is an Understatement – SIX ERP Just Works for you.

A deeper look at "software fit"

Common wisdom says that non-custom software will only be a 90% "fit" (at best) for an organization. Therefore, it's logical to assume that many companies would need third-party ERP integrations to cover the gaps with the fit. But being common wisdom doesn't make it right. Here are the areas that need to be explored before you consider integrating another solution into your ERP:

Get educated on existing software functionality. It's dangerous to look for an outside solution if you don't fully understand the ERP you are currently running. You bought an ERP system because you wanted an integrated solution. Don't start recreating your past environment with integrations. Remember, just because you or your team don't understand how to solve a business problem in the ERP, doesn't mean it can't be solved. There is no shame in lacking subject matter expertise in the ERP. Using a spreadsheet or another solution that you or your group understand is tempting, but there are low odds of this being the best solution in the long run. Reach out to an expert to help guide you to a solution within your existing ERP. It's the cheapest path in the long run.

Adapt your procedures to the software. There's an old saying, "Software should work for us, not the other way around." This statement is true, but adapting your processes to the software's functionality doesn't mean you work for the software; it means you use it! It's about increasing the efficiency of your business.

Think about Data

Performance reporting. There's a lot of data in the ERP database, and sometimes you don't see exactly what you want in the format you want. You may be just a short step from getting the information you want. When thinking about reports, don't just think about paper.

Many tools allow you to bring data to the screen, even in real time. Most ERP systems also allow you to transfer data to Excel (this is different from importing data into Excel, which should be avoided). Excel can, in most cases, also be configured to extract data from the ERP database. In both cases, Excel is used as the data presentation layer.

Customize the ERP system using the built-in tools. Every ERP software I have worked with has built-in tools that allow you to customize the software to your needs. You can add fields and features that fit your needs. This will enable you to handle any business situation within the core ERP solution. Note that I use the word "customization" and not "adoption." Customization means that you use the tools provided by the developers of the software. These customizations usually survive the upgrade. Customization means that the developer changes or enhances the software's source code only for the use case of your business. The end result is a unique version of the software. This can also make it difficult to update the software over time. I never recommend customizing the core software system.

Use "modular" functionality in your existing ERP system. Modular functionality is used when a solution is needed to supplement functionality already available in the ERP system.

"Plug-in" or modular functionality may exist to combine optimal software solutions with ERP. Here are a few examples:

E-commerce and ERP integration: when a customer orders products through the website, integration with the ERP system avoids re-entering purchases into the ERP system, which is time-consuming and error-prone. The e-commerce and ERP systems are synchronized in real-time.

Integration of a CRM solution and the ERP system: often, customers have an optimal customer relationship management (CRM) solution that is not integrated with their ERP system, mainly because integrating the vast amounts of data typically contained in CRM systems can be complex. Data may include customer information data, quotes, estimates, orders, shipments, invoices, unpaid balances, tasks, and follow-up activities related to each customer individually. A robust integration can be critical to a successful sales process. When integrating CRM and ERP systems, you need to discuss which system "owns" the data and whether the systems should be unilaterally or mutually integrated.

Carrier and ERP system integration: This integration makes sense if the company ships products through carriers such as UPS or FedEx. Information about the "to ship products" are sent to the carrier, or sometimes multiple carriers at once; the carrier sends the shipping charges, tracking numbers, and similar data back to the ERP system. In most cases, this allows finding the best shipping charges for your customers. All the shipping information resides in the ERP system. It can be used to communicate with customers (e.g., to inform customers of carrier choices, potential delivery dates and shipment tracking numbers).

Integration of a supply chain management/invoice payment solution and an ERP system: companies can automatically update their ERP system with an integration that helps manage the order process and delivery date. Nevertheless, any electronic system, and one more an ERP system, is only as good as what it contains – and that mainly refers to the data. These integrations ensure that suppliers confirm the order and that the product is delivered on the promised date. The ERP system, which uses this information to plan production and make management decisions, is updated accordingly. Accounts payable automation is also typically part of these solutions, with the integration automatically paying invoices to suppliers based on the parameters you set.

Integration of CAD and ERP systems: these integrations synchronize CAD (computer-aided design system) data with ERP data. Products are designed in the CAD system to obtain material specifications and routing. Instead of re-entering this information into the ERP system, the integration automatically transfers the data and creates the required materials in the ERP system.

Reasons for performing ERP integration with other software systems

If you are under the impression that I am trying to dissuade you from integrating ERP with another software package, you are partially correct. My real message is this:

Please don't do it for the wrong reasons. ERP integration should be the last choice when solving a business problem. Often, I've seen ERP integrations be the first or second choice, primarily because we use the tools we know, which leads to inefficiencies and unnecessary complex processes, often driven by human initiative.

That's not to say there aren't good reasons to integrate your ERP system with another software package. As in everything else, the key to success lies in executing a well-thought-out plan.

Here are the areas you should plan for before integrating ERP

Determine the data points. Determine what data needs to come in when it needs to go in, and in what direction commonly leads to a dilemma. Just because you can import data, doesn't mean you should or have to. Minimize the data points to reduce complexity initially, and increase over time – strictly when necessary.

Determine software alpha. This is in line with your data strategy. Typically, the ERP system should be the master of all the data available, so it is the alpha. Every other software package provides data to the ERP system. It's certainly not a strict standard, but in most cases it has shown that it is best practice to achieve a data master in organizations. Otherwise, you will create a lot of information silos, and that is not the desirable outcome as it will lead to clustered data.

Determine who should write the interface. Since ERP is usually the alpha software, the interface is generally written by someone who knows ERP very well. The help of an expert on the other software may be needed, but the ERP side will still drive the project.

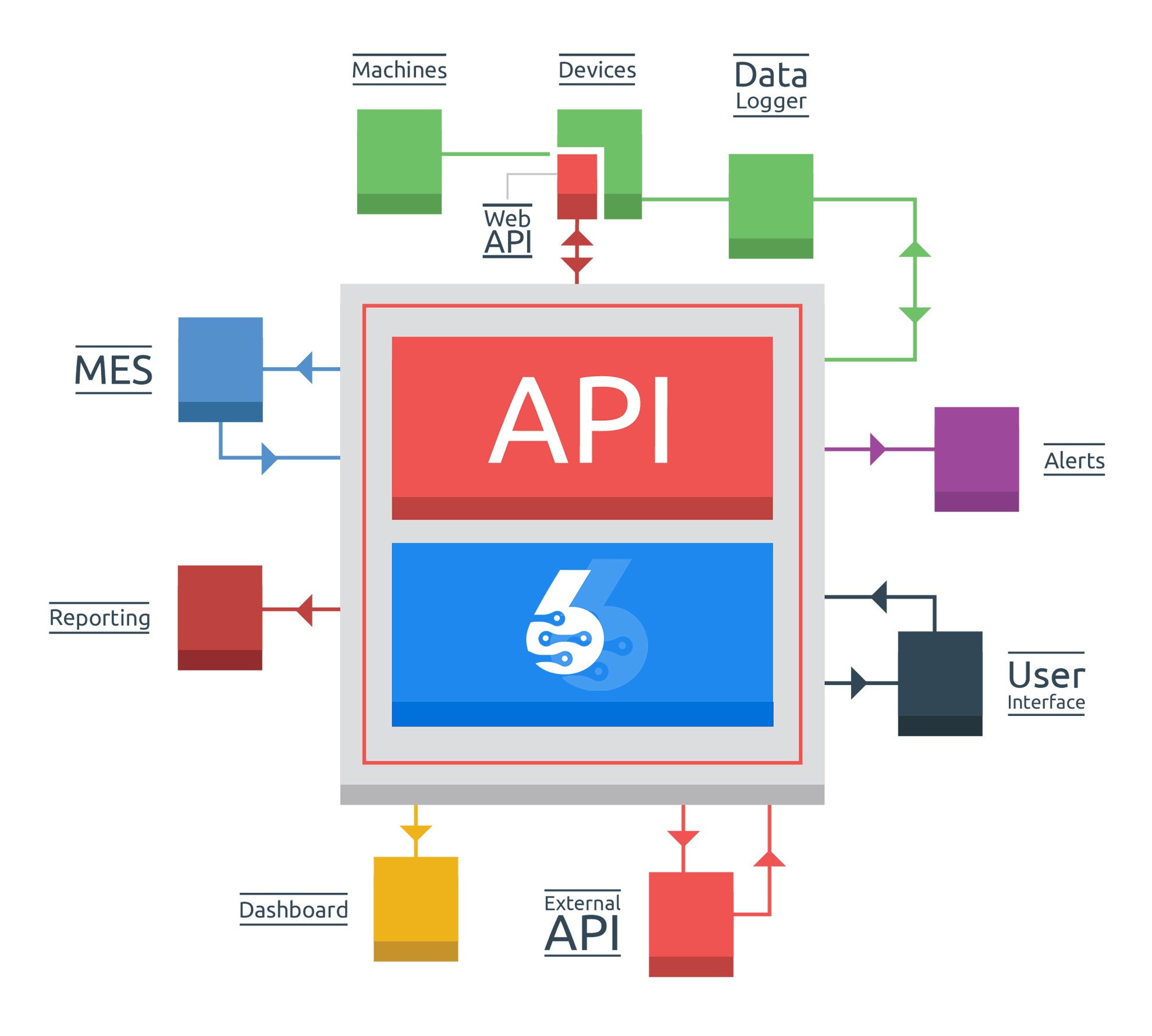

Determine the method for moving the data. Many options are available, from simple CSV file imports to API integrations. A specialist will determine the preferred method and the reasons for it.

Conclusion

I'd like to leave you with just one conclusion, and it is this: always make sure that the ERP expert is involved in the decision to integrate another software solution into the ERP to solve business problems. Andreas Maier is one of those experts; let him know if you want to talk to him.

SIX ERP is a highly customizable ERP solution that is cost-effective and the best choice for businesses. SIX ERP is a robust solution that includes flexible tools based on years of experience working with these solutions. We have helped our customers avoid complex third-party integrations and replace many "home-grown" solutions. Oh, what cost and pain they could have avoided if they had given us a shot first.

About the author

Andreas Maier is a results-driven CEO with nearly 30 years of experience in ERP, digital transformation, and IT consulting. He has held leadership positions in Fortune 100 companies such as rentalcars.com (PCLN) and Intrasoft International, a leading EU-based R&D software vendor. With a Ph.D. in Neural Networks from the University of Cologne, Andreas combines deep technical expertise with a strategic approach to business process optimization.

As the founder and co-founder of multiple successful startups, including XXL Cloud Inc., eShopLeasing Ltd, and WDS Consulting SA, his expertise lies in ERP consulting, IT strategy, and process automation. His work is focused on helping businesses implement scalable ERP solutions, streamline operations, and drive digital transformation.

Related articles

ERP Integrations - To Do or Not To Do?

This blog post will explore when you should and shouldn't execute an ERP integration.ERP integrations can offer a lot of potential benefits for companies. They can provide a way to...

Why Every Business Needs an ERP System

Every business needs an ERP system. An ERP, or enterprise resource planning, system is a software application that enables a company to automate and track tasks across all departments. By...