- Manufacturing

- 16.11.2025

MTO and MTS in Manufacturing

How Make-to-Order and Make-to-Stock work—and how SIX ERP blends them for faster delivery, smart customization, and steady profits

Dr. Andreas Maier

16.11.2025

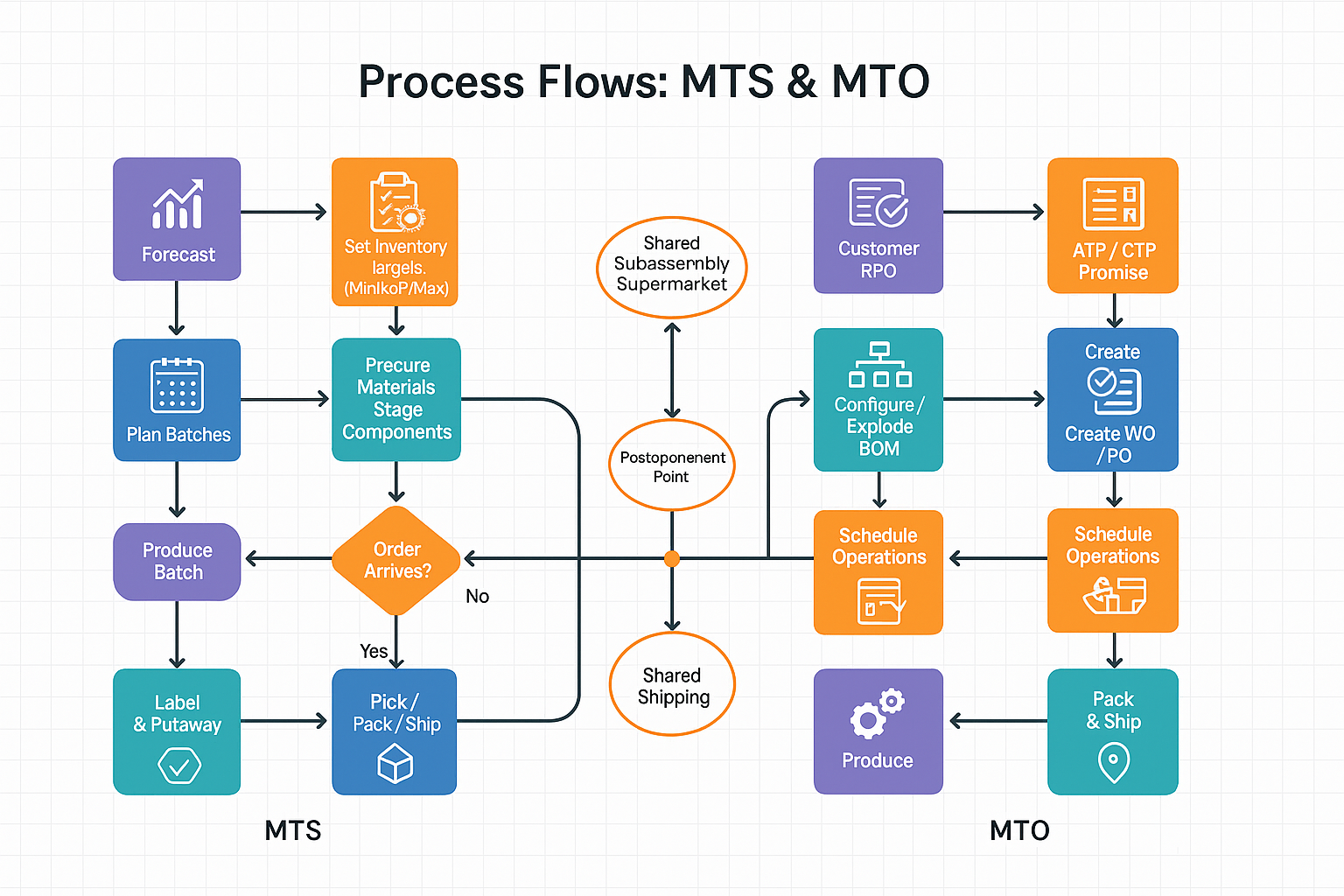

In manufacturing there are two core ways to plan and run production. The first is Make-to-Order (MTO). The second is Make-to-Stock (MTS). They are not enemies. They are tools for different situations. Some companies lean mostly on one model. Most successful companies combine both and switch between them as demand changes. In many cases parts of a product are made for stock, while the final steps are finished only after a customer order. This “hybrid” approach gives you both speed and flexibility.

Make-to-Order (MTO) means you start building after a real customer order arrives. The customer can choose options like size, color, firmware, packaging, or special testing. You plan materials, machine time, and people for that specific order, and you ship when the job is complete. The clear benefit is that you do not hold lots of finished goods in a warehouse, so you avoid the risk of slow movers and write-offs. The trade-off is lead time: the customer waits while you buy parts (if needed), set up the line, and produce the item.

Make-to-Stock (MTS) is the opposite. You build before orders arrive, guided by a demand forecast and target inventory levels. The goal is fast delivery—often same-day or next-day—because the item is already on the shelf. This is great for fast-moving products, repeat orders, and markets where delivery speed wins deals. The cost of that speed is higher inventory and forecast risk. If the forecast is off, you may carry too much stock or, in peaks, run out and miss sales.

In the real world, companies often blend the two. Imagine a standard pump: the housing and impeller are made for stock (MTS) so they are ready immediately, but the final configuration—nozzle, motor tuning, labeling, test report—is completed after the order (MTO). Delivery time stays short, while the customer still gets the exact variant they need. Hybrid flows like this are especially powerful when you have many variants, seasonal swings, or different service promises by market.

SIX ERP is built to support both MTO and MTS on the same platform, even for the same product family. For each item you can define whether it follows an MTO policy, an MTS policy, or a hybrid policy. The system then plans materials and capacity accordingly and gives a realistic promise date that sales can trust. If the market shifts, you can change the policy with a few clicks—moving an item from MTS to MTO, or the other way around—without breaking your upstream purchasing or your shop-floor schedule. This keeps operations stable and customer service fast and predictable.

In the next sections we will explain how MTO works step by step, how MTS works step by step, how to combine them safely, and how SIX ERP manages materials, capacity, costs, and delivery dates so you get shorter lead times, fewer errors, and stronger margins.

How Make-to-Order (MTO) works — from quote to shipment

Make-to-Order starts when a real customer places an order. Nothing is built in advance. The system first checks what you can honestly promise. In SIX ERP this is done with two checks working together: Available-to-Promise (ATP) looks at what materials and subassemblies you already have, and Capable-to-Promise (CTP) looks at machine time, people, and changeovers. With these two views the system proposes a realistic ship date instead of a guess.

After the promise check, the sales order is turned into actual work. The system “explodes” the Bill of Materials (BOM) to list every part and material you need, and follows the routing to see each operation in order (cutting, machining, coating, assembly, test). SIX ERP creates Work Orders (WO) for production steps and Purchase Orders (PO) for parts you do not have. If the item is configurable, variant rules pick the right components and operations automatically, so engineering does not have to redraw anything.

Planning then books time on the real resources. Capacity is not treated as infinite. The scheduler places each operation on a specific machine and shift, considers setup matrices (how long it takes to switch from Product A to Product B), and respects maintenance windows. If a resource is fully loaded, the system moves the work to the next available slot or suggests an alternate machine or an outside partner. This keeps the promise date honest and prevents overbooking that would cause delays later.

Execution is straightforward but disciplined. Materials are reserved to the job so someone else cannot use them by mistake. Operators receive digital instructions, drawings, and test limits at the workstation. As work progresses, they report quantities, time, and any scrap. Quality checks are embedded at the right steps, not just at the end. If a measurement drifts, the system stops the job and alerts the supervisor instead of letting bad parts reach final assembly. When the job passes final test, packing rules and labels are applied for that customer, including certificates if needed.

Costs are tracked per job so you can see the truth, not an average. SIX ERP collects actual material cost, actual labor time, and machine time, and compares them with the plan. You immediately see cost variance and the reasons behind it (more scrap than expected, extra setup, supplier price change). This helps you improve the next quote, adjust routings, or renegotiate with vendors. It also gives finance clean numbers for Work-In-Process (WIP) and margin per order.

MTO has clear strengths and common risks. The strengths are customization, low finished-goods inventory, and perfect traceability—every part and test links to a specific customer order. The risks are longer lead time and sensitivity to delays. Good controls reduce those risks: keep small safety stocks for long-lead “choke” parts, approve alternates and substitutes in advance, use realistic setup times, and protect your schedule with time fences so last-minute changes do not break today’s plan.

A short example makes this concrete. A customer orders 120 units of a custom pump on Monday. The critical seal has a five-day supplier lead time. Setup on the assembly line takes one day, and the line produces 60 units per day. ATP/CTP proposes shipment next Wednesday: five days to get the seals (Mon→Fri), one day to set up (Mon next week), two days to build (Tue–Wed next week), and ship right after final test on Wednesday. If the seal is a known bottleneck, you could keep a small buffer of seals on hand. Then the same order would ship this Friday instead of next Wednesday. That is the power of honest promising plus a few smart buffers in an MTO flow.

How Make-to-Stock (MTS) works — from forecast to fast delivery

Make-to-Stock starts before a customer order arrives. The goal is simple: keep enough finished goods on hand so most orders ship the same day. To do that, you first build a demand forecast. SIX ERP can use your sales history, seasonality, promotions, and known events to estimate how much you will sell next week and next month. The forecast is not a guess in the dark; it is a rolling calculation that is reviewed often and corrected when reality changes.

Once you have a forecast, you set inventory targets so the warehouse never gets too full or too empty. The basic targets are a Minimum level, a Reorder Point (ROP), and a Maximum level. The Minimum protects you from small bumps in demand. The Reorder Point is the “refill now” signal that leaves enough time to produce or buy more before you run out. The Maximum keeps you from flooding the shelves. If you prefer a demand-driven method, SIX ERP also supports buffer zones (green/amber/red) so planners can act on a simple signal rather than on a long report.

Planning then turns these targets into production orders. SIX ERP proposes lot sizes that fit your line: big enough to be efficient, small enough to stay flexible. The scheduler levels the plan across days and shifts, considers changeovers, and respects maintenance and labor limits. If demand is growing, the system will bring production forward. If demand is slowing, it will stretch the gap between batches so you do not build unnecessary stock.

Execution in MTS aims for steady rhythm. Operators see what to run, how much, and by when. Materials are backflushed or issued to the batch, and quality checks are placed at the right steps. Finished goods are labeled and moved to the correct location so they are easy to pick. When a customer order comes in, the fulfillment team can ship immediately because the product is already on the shelf. After each shipment, inventory drops and the system checks whether it has crossed the Reorder Point; if it has, a new batch is planned automatically.

Because MTS ties up cash in inventory, you need strong controls. SIX ERP tracks service level (fill rate)—the percentage of lines shipped straight from stock—alongside forecast accuracy (MAPE). If fill rate is low, you may need higher targets or shorter cycle times. If accuracy is poor, the system highlights SKUs with the worst error so you can adjust models or talk to sales about upcoming promotions. The system also watches aging and excess stock, so slow movers do not hide in the racks.

Supplier performance still matters in MTS. If a key component has long or unreliable lead time, a late delivery can stop your line and drain finished goods. To reduce that risk, SIX ERP lets you define alternate items, dual sourcing, and realistic safety stocks for critical parts. You can also see vendor on-time and in-full delivery performance, so purchasing can act before a problem becomes a stockout.

Here is a simple example. You sell a standard filter with stable demand around 100 units per week, and sometimes peaks to 130. You set a target of 300 units, a Reorder Point of 180, and a batch size of 300. Today you have 240 on hand. A customer orders 120 at 10:00. You ship at 14:00 from stock, and your on-hand drops to 120, which is below the Reorder Point. SIX ERP immediately plans a 300-unit production order for the next available slot. Tomorrow you start the batch, and by the following day the shelf is back near the target. The customer got fast delivery, the line ran efficiently, and your stock stayed within safe limits.

MTS shines when speed wins the sale and demand is reasonably steady. It does carry risk if the forecast is wrong. That is why the most effective teams review forecasts weekly, adjust targets monthly, and keep the plan flexible. With these habits, and with clear signals from SIX ERP, MTS gives you the best of both worlds: quick service for the customer and smooth, predictable work for the factory.

Smart Enough to Handle Everything, Simple Enough to Feel Like Magic.

How MTO and MTS work together — safe hybrids and smart switching

Most factories do not live in a pure world. Some products must be fast, others must be flexible. The practical answer is a hybrid flow: you make the common parts in advance (like housings, boards, standard sub-assemblies) and you finish the last steps after you get a real order. This pushes the decoupling point—the place where you switch from forecast-based work to order-based work—close to the customer. The result is short delivery time without losing the ability to customize.

A classic pattern is postponement. Imagine a controller sold in many variants. You keep the printed circuit board, enclosure, and standard accessories ready in stock. When an order arrives, you load the right firmware, run the final test, print the label, and ship. The early steps are Make-to-Stock (MTS); the last steps are Make-to-Order (MTO). Postponement also reduces the risk of writing off slow variants, because you delay the “variant choice” until the order is real.

Another practical pattern is a supermarket of semi-finished parts. You produce coils, frames, casings, or kits to a small target and hold them in a nearby area. Final assembly waits for the order. This feels like a small warehouse that feeds MTO. It smooths the line, keeps set-ups efficient, and still gives you the power to finish custom features quickly.

Sometimes you do not mix steps inside one product but rather split the catalog. Fast movers become MTS with clear inventory targets. Slow movers or high-value custom items stay MTO. Mid-range items can switch between the two with rules. For example, a product is MTS in peak season and MTO in off season. Or it is MTS for the top two variants and MTO for the rest. The important part is to make the rules explicit so sales, planning, and production act the same way.

Switching policies should be controlled but easy. In SIX ERP every item can have a planning policy: MTO, MTS, or Hybrid. You can also set where the decoupling point sits in the Bill of Materials (BOM)—at finished goods, at a sub-assembly, or at component level. If demand becomes unstable, you can move an item from MTS to MTO with a few clicks. The system updates buffers, lead times, and scheduling logic, and it keeps an audit trail so everyone knows who changed what and when. If demand stabilizes again, you can switch back to MTS and restore the previous targets.

To run hybrids safely you need three things: honest promising, clean inventory signals, and clear work instructions. Honest promising means you always check Available-to-Promise (ATP) for stock and Capable-to-Promise (CTP) for capacity before you give a date. Clean inventory signals mean you set and review Minimum, Reorder Point, and Maximum (or use buffer zones), so the team knows when to produce more without long meetings. Clear work instructions mean operators see exactly which steps are MTS and which are MTO, with the right drawings, test limits, and labels at each station.

Quality and finance also need attention in a hybrid. Quality must track what was tested in the MTS stage and what must be tested again after MTO finishing. Finance must separate Work-In-Process (WIP) for MTO jobs from the value of finished stock in MTS. SIX ERP handles both: quality checkpoints can be placed at any operation, and costing collects actual material and time by job or batch, then rolls it to the right ledger accounts. This keeps your On-Time-In-Full delivery (OTIF) stable while your books stay accurate.

Here are two short, real-world switches. First, demand becomes volatile for a standard pump. You switch the finished pump from MTS to MTO, but you keep the housing and motor as MTS sub-assemblies. Lead time to the customer grows a little—from one day to three days—but you cut write-offs and keep cash free. Second, a custom filter wins a big contract with steady weekly call-offs. You move it from MTO to MTS for the two main sizes, set a Reorder Point (ROP) and a target level, and keep exotic sizes as MTO. Service gets faster for most orders, while you avoid piling up rare variants.

When teams use hybrids, governance matters. SIX ERP lets you add approvals for policy changes, supplier alternates, and substitutions. It also shows the impact on key measures with clear names: service level (fill rate), forecast accuracy (MAPE), inventory turns, Days of Inventory on Hand (DOH), schedule adherence, and First-Pass Yield (FPY). With numbers like these on one screen, managers can decide when to push more to stock and when to hold back for order-driven work.

The message is simple: MTO and MTS are best friends when you place the decoupling point wisely and keep your rules visible. With the right signals and controls, you can offer fast delivery for common needs and true customization when it counts—on a single platform that keeps plans realistic and promises true.

How SIX ERP makes MTO and MTS work in real life — configuration, daily use, and proof with numbers

Software matters when it removes guesswork and keeps everyone on the same page. SIX ERP is built to run MTO and MTS side by side without confusion. The idea is simple: each item in your catalog has a planning policy. You choose Make-to-Order, Make-to-Stock, or a Hybrid setup. You also decide where the decoupling point sits—at a finished product, a sub-assembly, or even a component. Once these rules are saved, the system plans materials and capacity in the right way and gives sales a promise date that you can actually keep.

Setting up an MTO item starts with clean master data. You add or import the Bill of Materials (BOM), the routing with the real operations and setup times, and the suppliers with their normal and worst-case lead times. When a sales order arrives, the system links a Work Order to that order, reserves materials, and books time on the right machine and shift. If the part is configurable, the system picks the correct variant automatically, so engineering does not need to redraw. During execution operators see clear digital instructions, quality checks are built into the steps, and costs are collected per job, so you know the real margin of that order.

Setting up an MTS item is different but just as precise. You define a forecast or let the system build one from history and seasonality. You choose Minimum, Reorder Point, and Maximum levels, or use buffer zones if you prefer a demand-driven method. The planner then approves the suggested batches. The schedule evens out the work across days and shifts, so you avoid peaks and dry spells. When stock drops below the Reorder Point, the system raises a planned order at once. This is how you keep delivery very fast while avoiding too much inventory.

Hybrid items combine the two without tricks. For example, you can keep a controller’s board and housing as stocked sub-assemblies, but finish firmware and final test to order. In the item file you tag the sub-assemblies as MTS and the final operations as MTO. The system now knows that early steps follow the stock signals, while the last steps follow the customer order. Sales still gets one promise date; production still gets one clean set of instructions; finance still sees the right costs in the right accounts.

Daily work becomes easier because each team sees what matters. Sales checks Available-to-Promise for stock items and Capable-to-Promise for MTO items, then commits a honest date. Planning reviews forecasts, buffers, and capacity, and turns planned orders into real work. Purchasing sees which parts are critical, which have alternates, and which suppliers are slipping. Production runs work orders with barcode scans that record time, scrap, and completed quantity. Quality places tests at the correct operations and can print certificates linked to the job or lot. Finance tracks Work-in-Process, values finished stock, and sees cost variance and its causes, like extra setup or supplier price changes.

To prove that the system is working, SIX ERP shows a small set of clear measures on one screen. You can watch On-Time-In-Full delivery (OTIF) to see how often you ship when promised and in the full quantity. You see service level (fill rate) for stocked items to learn how often you ship straight from the shelf. You track forecast accuracy (MAPE) so you know which items need better models or more frequent review. You follow inventory turns and Days of Inventory on Hand (DOH) to keep cash under control. On the shop floor you look at plan adherence, schedule adherence, changeover time, First-Pass Yield (FPY), scrap, and rework. These numbers are simple to read, but they tell the full story and drive the right actions.

The last piece is change without chaos. Markets move. A product that used to be stable can become volatile. With SIX ERP you can switch an item from MTS to MTO or back again using a controlled change with approvals. The system updates planning rules, buffers, and promise logic automatically and keeps an audit trail of who changed what and when. Open orders and schedules are adjusted in a safe way. This is how you stay flexible without losing control.

In short, SIX ERP turns MTO and MTS from theory into smooth daily practice. You define clear rules once, the system plans and schedules according to those rules, teams get the right information at the right time, and management sees proof in the numbers. The result is shorter and more reliable delivery times, lower waste, better use of machines and people, and margins you can trust.

Short, real-world examples — side by side

Let’s make the ideas concrete with three simple stories. They use round numbers so you can follow the logic without a calculator. The goal is to show how Make-to-Order (MTO), Make-to-Stock (MTS), and a Hybrid flow behave in real life.

Example 1: Standard water filter (MTS)

A distributor buys the same filter every week. Average demand is about 100 units per week, with peaks up to 130. Your target on the shelf is 300 units. The Reorder Point is 180, and your usual batch is 300. On Monday morning you have 240 in stock. At 10:00 the distributor orders 120. You ship the same day and stock drops to 120, which is below the Reorder Point. SIX ERP immediately plans a new batch of 300 and places it in the next free slot in the schedule. You start on Tuesday, finish on Wednesday, and the shelf climbs back toward 300. The customer gets fast delivery, your team runs a clean batch, and cash is not locked for too long because targets are sensible and reviewed monthly.

Example 2: Custom pump with special seal (MTO)

A factory needs 120 pumps with a seal that you do not keep on hand. The seal lead time from your supplier is five days. Setup on your assembly line takes one day. The line can build 60 pumps per day. SIX ERP checks what is Available-to-Promise (stock and parts) and Capable-to-Promise (machines and people) and proposes a ship date nine days from today: five days to receive seals, one day for setup, two days to build, and one day to test and pack. If this seal is a known bottleneck, you can keep a small safety stock of, say, 60 seals. In that case the same order ships four days sooner. You pay a bit more to hold the seals, but you win on lead time. The system shows both options, so sales and planning can choose together.

Example 3: Hybrid controller (MTS base + MTO finish)

You sell a controller with many firmware versions and labels. The printed circuit board and housing are common for all variants, so you keep them as sub-assemblies in stock. When an order arrives, you load the right firmware, run final tests, and print the label. This last part is Make-to-Order. A customer orders 50 controllers at noon. Because the base kits are on the shelf, your team only needs to program and test. You ship by tomorrow afternoon. If orders pause for a week, you are safe: you are not stuck with finished goods in rare versions, only with base kits that all variants share. This lowers the risk of write-offs and still keeps delivery fast.

What do these stories teach? MTS wins on speed when demand is steady and known. MTO wins on flexibility and low stock risk when items vary a lot or are expensive. The Hybrid approach finds a smart decoupling point—often a shared sub-assembly—so you get the speed of MTS and the choice of MTO at the same time. SIX ERP supports all three without hacks. You define the rules once per item, the system plans the right way, and you can change the rules later if the market moves.

Measuring success and getting started — simple metrics and a safe rollout

A good system proves itself with numbers that everyone understands. Start with a small set of clear metrics and review them every week. This keeps attention on results, not on guesses.

First, watch on-time and in-full delivery (OTIF). This tells you how often you ship when you promised and in the full quantity. If OTIF is low in Make-to-Order, the usual reasons are supplier delays, long changeovers, or overbooked machines. If OTIF is low in Make-to-Stock, you may be running out of stock because targets are too low or the schedule is not keeping up. Next, track service level (fill rate) for stocked items. This is the share of orders that you can ship directly from inventory without waiting. A high fill rate means customers get fast delivery; a low fill rate means you need better forecasts or faster replenishment.

Then, look at forecast accuracy. A simple measure is the average percentage error between what you predicted and what really sold. If the error is large, adjust the model, shorten the review cycle, or separate the item into seasons or channels. Follow inventory turns and days of inventory on hand. These show how fast stock moves and how long it will last if sales continue at the current pace. If turns are low and days on hand are high, cash is stuck on the shelf and you should lower targets or reduce batch sizes. On the shop floor, keep an eye on plan adherence (did we build what we planned), schedule adherence (did we build it when we planned), changeover time, first-pass yield, scrap, and rework. These reveal where time and quality are lost.

With the metrics in place, start your rollout in thin slices. Pick one product family and decide which items are Make-to-Order, which are Make-to-Stock, and which will be hybrid. In SIX ERP you set the policy per item and, if needed, choose the decoupling point in the bill of materials. Enter or clean the bill of materials, routings, and supplier lead times. For Make-to-Stock items, set the minimum, reorder point, and maximum, or define buffer zones. For Make-to-Order items, make sure the Available-to-Promise and Capable-to-Promise checks have the right data for materials, machines, and labor calendars.

Run the pilot for four to eight weeks. Do not try to change everything at once. Let sales use the promise dates, let planning approve the suggested batches, and let production report time, scrap, and completions with barcode scans. Review the metrics weekly. If you see frequent stockouts on Make-to-Stock, raise the reorder point or shorten the production cycle. If Make-to-Order jobs miss dates because of one long-lead component, add a small safety stock only for that component. Adjust one thing at a time and measure again.

After the pilot shows steady results—higher OTIF, better fill rate, fewer rush changes—scale to the next product family. Reuse what worked: the same planning rules, the same report layouts, the same meeting rhythm. Add approvals for policy changes so switching an item from Make-to-Stock to Make-to-Order (or back) is controlled and visible. Keep an audit trail so everyone knows who changed what and when. Once a month, run a short review to update forecasts, reset targets, and clean up slow or obsolete items.

Throughout this process, SIX ERP keeps all teams aligned. Sales sees realistic dates. Planning sees clear signals. Purchasing sees supplier performance and alternates. Production sees simple work instructions. Quality sees the right tests at the right step. Finance sees true job costs, true stock value, and clear reasons for variance. With this shared view, Make-to-Order and Make-to-Stock stop being theory and become a calm, repeatable way of working that delivers fast, keeps cash under control, and supports growth.

Conclusion — choosing, combining, and growing with confidence

Make-to-Order (MTO) and Make-to-Stock (MTS) are not rival camps; they are planning tools for different realities. MTO shines when customers want options, when products are costly or complex, and when you must trace every step back to a specific order. It protects you from piling up slow-moving stock, but it needs honest promise dates and tight coordination with suppliers and machines. MTS shines when demand is steady and speed wins the deal. It gives same-day delivery and smooth production, but it ties up cash and depends on a forecast that must be checked and corrected often. Most modern factories need both. The smart move is to place the decoupling point—where you switch from forecast-driven to order-driven work—at a level that balances speed and choice. That might be a sub-assembly shared by many variants, or a base kit finished only after the order arrives.

SIX ERP is built for this mixed world. You can set the policy per item—MTO, MTS, or Hybrid—define where the decoupling point sits in the Bill of Materials, and let the system plan materials and capacity accordingly. Sales sees Available-to-Promise for stocked items and Capable-to-Promise for order-driven jobs, so dates are realistic. Planning gets clear signals: Minimum, Reorder Point, and Maximum for MTS, and job-linked work orders for MTO. Production runs with simple digital instructions and in-process quality checks. Purchasing manages alternates and supplier performance before problems hit the line. Finance sees true job costs, true stock value, and clean variance reasons. When the market shifts, you can switch an item from MTS to MTO or back again with approvals and an audit trail, without throwing schedules into chaos.

If you are starting this journey, begin small: classify one product family, set the policies, clean the master data, and run for four to eight weeks. Measure what matters—on-time and in-full delivery, service level from stock, forecast accuracy, inventory turns, first-pass yield—and adjust one lever at a time. As results stabilize, expand to the next family and repeat. Over a few cycles you will see shorter and more reliable lead times, fewer rush changes, lower scrap, and healthier margins. That is what a good system does: it turns planning ideas into everyday habits, visible numbers, and steady improvement. With SIX ERP, MTO and MTS stop being theory and become a practical way to deliver faster, customize wisely, and grow with confidence.

Are you facing challenges in your business that you're trying to solve?

Let’s connect for a FREE 30-minute consultation call and see how I can help you move forward.

12–18-Month Implementation Roadmap for Hybrid MTO/MTS

- Months 1–3 | Discovery & Design

- Map end-to-end processes; classify items as MTO/MTS/Hybrid; define decoupling points.

- Clean master data: BOMs, routings, work centers, vendors, lead times, item policies.

- Set KPIs and governance (approvals, audit trail, change control); draft training plan.

- Months 3–6 | Core Platform Setup

- Configure planning: Min/ROP/Max or buffers (DDMRP), lot sizing, calendars, ATP/CTP.

- Set up costing (standard + actual), QA checkpoints, traceability, and serialization.

- Integrate finance, inventory, barcodes/scanners; prepare data migration and test cases.

- Months 6–9 | Pilot (One Product Family)

- Migrate scoped data; train roles (sales, planning, purchasing, production, QA, finance).

- Run live orders; measure OTIF, fill rate, forecast accuracy, plan/schedule adherence, FPY.

- Fix gaps (alternates, safety stocks, setup matrices); stabilize daily routines.

- Months 9–12 | Wave 2 Scaling

- Add 2–3 product families; extend supplier alternates, dual sourcing, and lead-time controls.

- Introduce IIoT where useful (OEE, condition monitoring); refine scheduling and changeovers.

- Expand dashboards; formalize weekly ops review and monthly KPI review.

- Months 12–15 | Enterprise Rollout

- Onboard remaining families/locations; standardize work instructions and labels/certificates.

- Optimize buffers/targets by ABC class; tune forecasts (seasonality, promotions).

- Harden security, roles, and approvals; finalize disaster recovery and backup.

- Months 15–18 | Stabilization & Optimization

- Benchmark results vs baseline; reduce excess/obsolete stock; raise service levels.

- Activate advanced analytics (demand sensing, variance analysis); tighten cash-to-stock.

- Hand over cadence: weekly S&OE, monthly S&OP/KPI, quarterly policy reset; continuous training.

Glossary — clear terms with short forms in brackets

Understanding the words makes the whole topic easier. Here are the key terms we used, written in plain language, with the usual short forms in brackets.

Make-to-Order (MTO)

You start building only after a customer orders. Good for customized items and costly products. Lower finished-goods stock, but longer lead times.

Make-to-Stock (MTS)

You build before orders arrive, based on forecasts. Great for fast delivery and steady lines. Needs more inventory and careful control.

Bill of Materials (BOM)

A structured list of everything needed to make a product—parts, materials, and sometimes sub-assemblies. Think of it as the recipe.

Routing

The ordered list of manufacturing steps—machines, operations, and setup times. Think of it as the cooking instructions for the recipe.

Available-to-Promise (ATP)

A check of what is already in stock or on firm inbound orders, so you can give a realistic ship date for stocked items.

Capable-to-Promise (CTP)

A check of real capacity—machines, people, changeovers—plus material lead times, to give a realistic ship date for make-to-order jobs.

Work Order (WO)

The instruction packet for the factory: what to build, how many, by which route, and by when.

Purchase Order (PO)

The formal order sent to a supplier to buy parts, materials, or services.

Decoupling Point

The handover point where planning switches from forecast-driven (MTS) to order-driven (MTO). Placing it well balances speed and customization.

Minimum / Reorder Point / Maximum (Min/ROP/Max)

Simple inventory targets. Minimum protects against small demand bumps, Reorder Point tells you to replenish now, Maximum prevents overstock.

Demand-Driven Material Requirements Planning (DDMRP)

A buffer-based method that uses colored zones (green/amber/red) to signal when to make or buy, reducing noise from bad forecasts.

On-Time-In-Full (OTIF)

How often you ship orders on the promised date and with the full quantity. A core service measure.

Service Level (Fill Rate)

The share of order lines you can ship straight from stock without waiting. A key MTS measure.

Forecast Accuracy (MAPE)

Mean Absolute Percentage Error. A simple way to show how far the forecast is from reality, on average.

Inventory Turns / Days of Inventory on Hand (Turns/DOH)

How many times per year stock is sold and replaced (turns), and how many days current stock would last at the present sales pace (DOH).

First-Pass Yield (FPY)

The percent of items that pass all tests the first time, without rework. A clean quality signal.

Work-in-Process (WIP)

Value of items that are started but not yet finished. Important for both scheduling and finance.

Cost Variance

The gap between planned cost and actual cost (materials, labor, machine time). Shows where money leaks and where to improve.

Postponement (Hybrid MTS→MTO)

Make shared base parts to stock, finish options after the order. Shortens delivery while keeping flexibility.

Alternate / Substitute Item

Approved backup parts you can use if the main part is not available, so production does not stop.

Schedule Adherence / Plan Adherence

Did we run the batch when we said we would (schedule), and did we build the mix and quantity we planned (plan)?

About the author

Andreas Maier is a results-driven CEO with nearly 30 years of experience in ERP, digital transformation, and IT consulting. He has held leadership positions in Fortune 100 companies such as rentalcars.com (PCLN) and Intrasoft International, a leading EU-based R&D software vendor. With a Ph.D. in Neural Networks from the University of Cologne, Andreas combines deep technical expertise with a strategic approach to business process optimization.

As the founder and co-founder of multiple successful startups, including XXL Cloud Inc., eShopLeasing Ltd, and WDS Consulting SA, his expertise lies in ERP consulting, IT strategy, and process automation. His work is focused on helping businesses implement scalable ERP solutions, streamline operations, and drive digital transformation.

Related articles

Building an ERP training schedule for your organization

Creating an ERP training schedule is perhaps the most essential part to a successful implementation. It requires careful planning and consideration to ensure that all employees have sufficient knowledge to...

Understanding Warehouse Management Solutions

A warehouse management system (WMS) is a software application that supports the day-to-day operations in a warehouse. A WMS helps to control and direct the movement of materials within a...